What We Do

Core Business

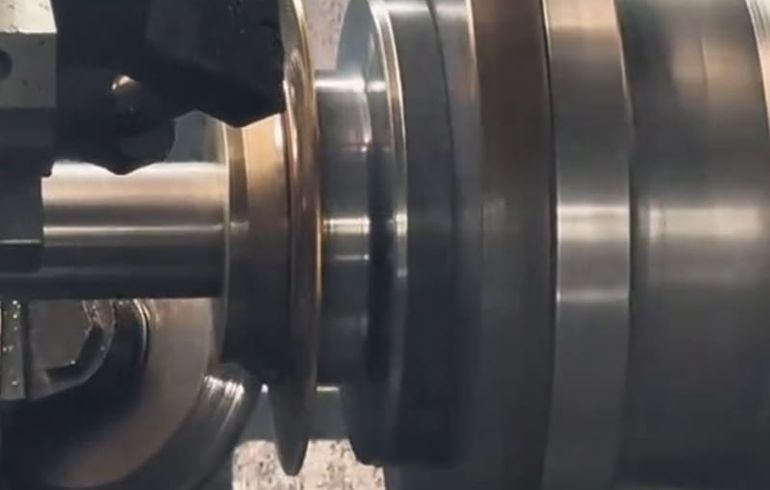

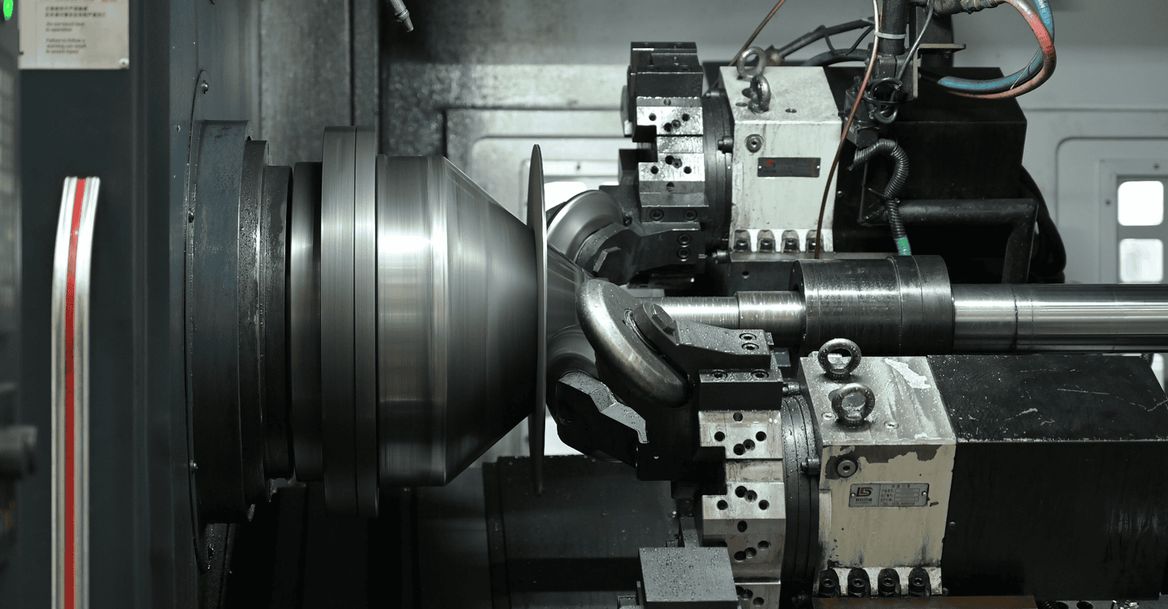

CNC Spinning for Metal Components - Metal Spinning & Flow Forming for aluminum, stainless steel, carbon steel, titanium, and high-temperature alloys

Die & Tooling Design and Manufacturing - Tooling & Die Design ensuring precision and process repeatability

Robotic Laser Welding - Precise, clean, and visually smooth welds with consistent quality

3D Laser Cutting - 3D Laser Cutting for dimensional accuracy and surface quality

OEM/ODM Support - From prototyping to mass production, small batches to large runs — all tailored to your needs.

Why Choose Us

Manufacturing Capabilities

Advanced Equipment - CNC Spinning Range (10–50) tons,Equipped with high-precision CNC spinning machines for ordinary, strong, internal & external spinning.

Material & Size Flexibility - Process aluminum, stainless steel, copper, titanium alloys with diameters up to Ø3000 mm and thickness up to 15 mm.

Precision & Efficiency - Tolerance - ±0.2 mm (standard) / ±0.1 mm (aerospace grade), material utilization rate above 95%.

How We Do

Equipment & Quality Assurance

Quality & Process Control

- Real-time Monitoring with Laser Measurement and Machine Vision

- Non-destructive Testing (Ultrasonic, Magnetic, and Dye Penetrant)

Advanced Equipment

- 5-axis CNC Spinning Machines (Lefeld Technology, Germany)

- Heavy-Duty Horizontal Spinning Units (up to 3000mm diameter)

- CMM 3D Coordinate Measuring Machine

- 3D Laser Cutting Machine

- Servo Robotic Laser Welding Station (Trumpf,Germany)

King Metal Spinning Co., Ltd

King Metal Spinning Co., Ltd [ KMS is the abbreviation ] is a leading manufacturer and designer of metal spinning products in China. Specializing in advanced metal spinning technology, KMS provides high precision customized spinning solutions to enhance product quality and strengthen clients’ market competitiveness.

Our products are widely used across aerospace, power electronics, petrochemicals, mechanical engineering, medical devices, agricultural machinery, and construction industries. With over two decades of technical expertise, KMS has established long-term partnerships with global enterprises, delivering high-precision spun components that empower customers to capture greater market share.

Guided by the principles of “Precision, Efficiency, and Excellence”, we offer end-to-end services covering design, process development, and intelligent manufacturing. Through continuous technological innovation, KMS has overcome the challenges of thick-plate, high-precision spinning, ensuring aerospace-grade surface integrity and dimensional accuracy.

Located in the Shifang Economic Development Zone, Deyang City, Sichuan Province, KMS operates multiple CNC spinning machines ranging from 10 to 50 tons, capable of processing up to Ø3000 mm diameter and 15 mm thickness steel plates. We warmly welcome global partners to visit and explore cooperation opportunities toward a shared future of innovation and excellence.

Our Vision

Guided by the values of Precision, Efficiency, and Excellence, Our factory is committed to becoming a global benchmark in metal spinning manufacturing.Through continuous innovation and intelligent production, we aim to empower industrial partners worldwide and drive the advancement of high-end equipment manufacturing.

We aim to empower industrial partners worldwide and drive the advancement of high-end equipment manufacturing.

King Metal Spinning Co., Ltd | KMS

English

English

Deutsch

Deutsch

Русский

Русский

العربيّة

العربيّة