About King Metal Spinning Co., Ltd

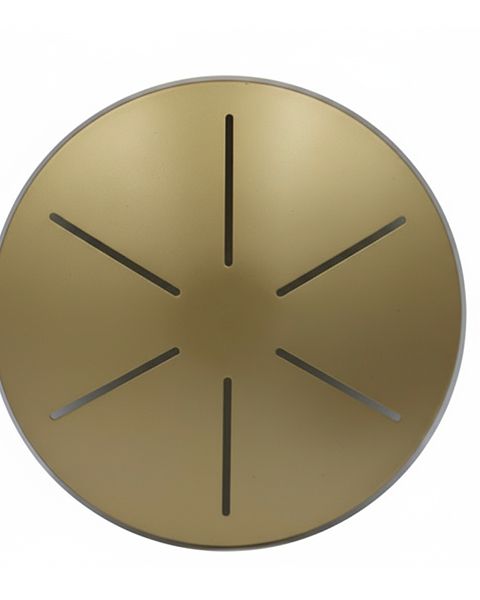

Metal Spinning & Forming for aluminum, stainless steel, carbon steel, titanium, and high-temperature alloys (metal cone,metal cylinder etc.)

Tooling & Die Design ensuring precision and process repeatability

Laser Welding with Robotic station

3D Laser Cutting for dimensional accuracy and surface quality

OEM/ODM Support From prototyping to mass production, small batches to large runs — all tailored to your needs.

Maximum Workpiece - Maximum Workpiece Ø3000 mm, thickness up to 15 mm

CNC Spinning Range - CNC Spinning Range 10 – 50 tons

Tolerance - Tolerance ±0.2 mm (standard) / ±0.1 mm (aerospace grade)

Surface Finish - Surface Finish Seamless spinning for flawless surface integrity

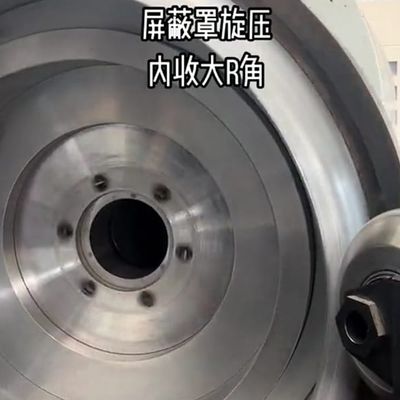

Thick Plate High-Precision Spinning - crack-free forming of 15mm high-strength steel.

Material Database R&D - optimized spinning parameters for titanium and superalloys.

Online Inspection System - laser measurement and vision detection ensure 99.8% yield.

Green Manufacturing - servo-driven machines and “Spin-to-Mill” technology reduce waste by 90%.

5-axis CNC Spinning Machines

Heavy-Duty Horizontal Spinning Units (up to 3000mm diameter)

CMM 3D Coordinate Measuring Machines

3D Laser Cutting Machine

Servo Robotic Laser Welding Station

King Metal Spinning Co., Ltd

In the modern manufacturing industry, the precise molding of parts and components is directly related to the performance, cost and competitiveness of the product, and mechanical spinning technology, as an efficient and high-precision metal forming process, is becoming a key choice for many industries to achieve high-quality manufacturing. KMS Mechanical spinning engineering, relying on many years of experience in the field of spinning, advanced equipment system and exquisite technology, provide customers in various industries with customized, high-quality spinning solutions to help enterprises break through manufacturing bottlenecks and achieve the dual improvement of production capacity and quality.

What is mechanical spinning ? Why choose us ?

Mechanical spinning is the process of gradually shaping sheet metal or pipe into various types of rotationally symmetrical parts through rotational movement and pressure. Compared with traditional stamping, casting and other processes, it has significant advantages such as high material utilization rate (up to more than 95%), high molding accuracy [Tolerance: ±0.2 mm (standard) / ±0.1 mm (aerospace grade)], and excellent mechanical properties of raw materials and parts.Whether it is a thin-walled cylinder, a tapered part, a hemispherical part, or a special-shaped spinning part with a complex curved surface, we can accurately control every molding detail.

Choosing us, the core lies in the three core competitiveness

Strong equipment

The factory is equipped with a number of high-precision CNC spinning machine tools, covering a variety of process types such as ordinary spinning, strong spinning, internal spinning, and external spinning. It can handle a variety of metal materials such as stainless steel, aluminum, aluminum, titanium alloy, etc., with a maximum workpiece diameter: Ø3000 mm and maximum Thickness: aluminum & steel up to 15 mm, stainless steel up to 10 mm which meets the different needs from small batch customization to large-scale production.

Experienced craftsmanship

Our technical team has an average of more than 10 years of research and development and practical experience in spinning technology, and can quickly formulate reasonable spinning solutions based on the drawings or samples provided by customers to solve common problems such as wrinkling, cracking, and accuracy deviation in the molding process.For parts with difficult and complex structures, simulation analysis and process optimization can also be used to ensure that the pass rate of one-time molding exceeds 98%.

Strict quality control

From the entry inspection of raw materials, to the real-time monitoring of the spinning process, to the dimensional inspection, mechanical properties testing and surface quality acceptance of finished products, we have established a full-process quality control system. All products meet the relevant national standards and the personalized quality requirements of customers, so that customers can place orders with confidence and use them with peace of mind.

Covering multiple industries, customized solutions show strength

With in-depth mastery and flexible application of spinning technology, our products and services have widely covered a number of key industries, providing targeted customized solutions for customers in different fields.:

Automobile industry

It can produce spinning parts such as automobile exhaust system pipe fittings, shock absorber housings, wheel hub decorations, etc. To meet the requirements of automobile manufacturing for lightweight, high-strength and high-precision parts, and help automobile companies improve product performance and market competitiveness.

Medical device industry

In view of the strict requirements of medical devices for the cleanliness, surface smoothness and structural stability of parts, we can customize the production of stainless steel cavities, catheter connectors and other spinning products in medical equipment to ensure that the products comply with the relevant regulations and standards of the medical device industry.

New energy industry

In the fields of new energy vehicle battery shells, photovoltaic bracket connectors, wind power equipment parts, etc., we optimize the spinning process to achieve the integrated molding of parts, reduce welding links, improve the sealing and corrosion resistance of parts, and provide reliable parts support for the development of the new energy industry.

Hardware appliance industry

It can mass produce rice cooker liner, pressure cooker shell, lamp reflector and other hardware home appliance spinning parts. With efficient production efficiency and stable product quality, it has become a long-term partner of many hardware home appliance companies to help customers reduce production costs and shorten delivery cycles.

In addition, in the fields of aerospace, construction machinery, daily hardware, etc., we have also accumulated a wealth of project experience, and can respond quickly and accurately according to the special needs of customers. Research and development, provide spinning solutions that exceed customer expectations.

Service guarantee

from demand to delivery, the whole process is worry-free, We know that high-quality products are inseparable from perfect service support. In order to make customers feel convenient and at ease in every aspect of cooperation with us, we have established a comprehensive service system.

Early communication

Professional business consultants and technical engineers will take the initiative to connect with customers, gain an in-depth understanding of customers' product needs, performance requirements, production batches and delivery cycles, and provide customers with detailed technical advice and program quotations to ensure that customers are clear and clear about the content of cooperation.

Sample trial production

Before the official mass production, we will make samples according to customer needs and invite customers for inspection and confirmation. If customers have adjustment opinions, we will optimize the process in time until the samples meet customer requirements, and then start mass production to avoid cost waste caused by program deviations.

Production follow-up

After the customer places an order, we will feedback the production progress to the customer in real time, so that the customer can keep abreast of the production situation of the product; if the customer has urgent order needs, we can start the expedited production process, under the premise of ensuring quality, shorten the delivery cycle as much as possible to meet the customer's urgent production needs.

After-sales support

After the product is delivered, we will conduct regular customer return visits to understand the use of the product. If the customer encounters any problems during use, we will respond within 24 hours and provide technical guidance and solutions in time to ensure that the customer's production work is not affected.

Choose us to start an efficient and accurate spinning cooperation journey

In the increasingly competitive manufacturing market, choosing a professional and reliable mechanical spinning factory is a key step for enterprises to improve manufacturing efficiency, reduce costs, and ensure product quality.We Mechanical spinning engineering, always take “technology-based, quality-oriented, customer-oriented” as our business philosophy, and are committed to becoming a high-quality partner for customers in various industries in the field of spinning.

Whether you need customized parts in small batches or standardized products in large quantities; whether you come from the automotive, medical, new energy industries, or other fields that require spinning parts, we are confident and capable of providing you with the most suitable spinning solution.

Now, you may wish to Contact US and let our professional team tailor an exclusive spinning plan for you, and work together to use precise spinning molding technology to enable your product upgrade and enterprise development!

We aim to empower industrial partners worldwide and drive the advancement of high-end equipment manufacturing.

King Metal Spinning Co., Ltd | KMS

English

English

Deutsch

Deutsch

Русский

Русский

العربيّة

العربيّة