Metal Spinning Design Considerations

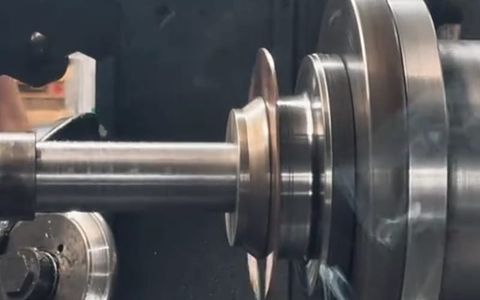

With continuous advancements in metal spinning technology and CNC spinning equipment, manufacturers are now able to achieve significantly tighter tolerances than ever before. While metal spinning offers excellent consistency and efficiency, it is important to understand its design limitations and capabilities to ensure optimal part performance.

Metal Spinning Tolerances

Modern CNC metal spinning machines enable precise control over wall thickness, diameter, and concentricity. As a result, metal spinning can achieve tight tolerances suitable for many industrial and aerospace applications. However, compared to milling or CNC machining, metal spinning remains a forming process rather than a cutting process, and absolute dimensional precision is subject to material behavior and forming dynamics.

Shape Considerations

Metal spinning is best suited for rotationally symmetrical (concentric) components. All spun parts are inherently round, making the process ideal for cones, cylinders, hemispheres, and other axisymmetric geometries.

Because of this rotational symmetry, metal spinning allows for flexible radius transitions and smooth contour profiles that are difficult or costly to achieve through traditional machining methods.

English

English

Deutsch

Deutsch

Русский

Русский

العربيّة

العربيّة