Spin Forming

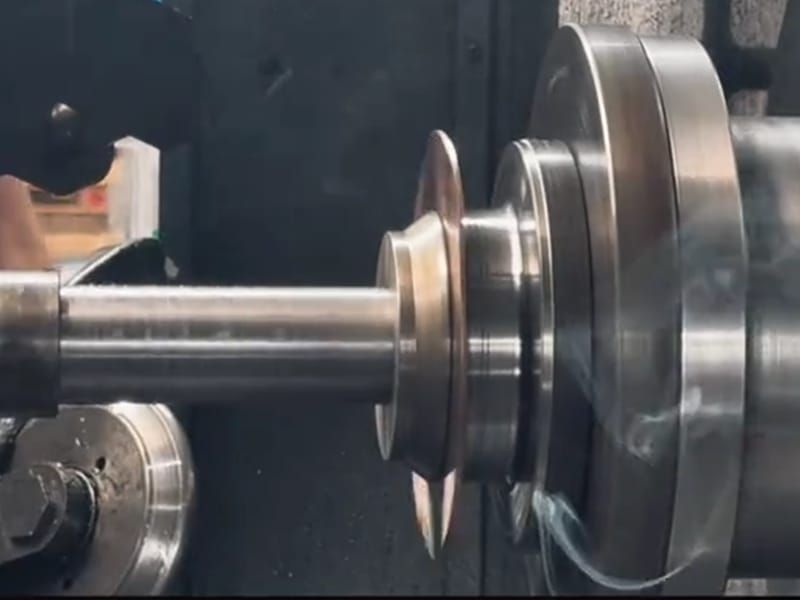

Spin forming, also referred to as metal spinning, is an advanced metal forming process used to manufacture axially symmetrical components by rotating metal blanks at high speed while applying controlled forming pressure.

Spin forming is a precision metalworking process in which flat metal sheets or tubes are progressively shaped over a mandrel through high-speed rotation and axial forming forces. The mandrel acts as a forming mold, enabling the production of complex geometries with excellent dimensional accuracy and surface finish.

The process typically begins with a flat blank or preform mounted on a CNC or manual spinning lathe. Depending on part diameter and geometry, the setup may include a headstock, tailstock, and follower to ensure stable support of the mandrel. As the workpiece rotates, specialized forming tools apply continuous pressure, gradually shaping the metal through controlled axial strokes until the final profile is achieved.

Spin forming is widely used in industrial and high-performance applications due to its ability to produce strong, lightweight components with consistent wall thickness and high structural integrity. Typical applications include pressure vessels, gas cylinders, fittings, satellite dishes, and aerospace structural components. The process is particularly valued in aerospace manufacturing, where tight tolerances, smooth surface finishes, and mechanical reliability are critical.

This metal forming method is well suited for materials such as stainless steel, carbon steel, aluminum, copper, and brass. By precisely controlling wall thickness and material flow, spin forming enables the production of components with high tensile strength and durability, even under extreme operating conditions.

At KMS, we fully leverage advanced spin forming technology to deliver components that meet or exceed aerospace and industrial standards. From heavy fabrication and certified welding to machine frames and complex formed assemblies, our metal spinning capabilities are engineered to support your most demanding projects. If you are seeking a reliable partner for high-quality metal fabrication with competitive pricing and fast lead times, KMS is ready to support your requirements.

English

English

Deutsch

Deutsch

Русский

Русский

العربيّة

العربيّة