Modernization of Metal Spinning

Automation has transformed metal spinning into a more reliable, consistent, and cost-effective manufacturing solution for modern industrial applications.

CNC Automation in Metal Spinning

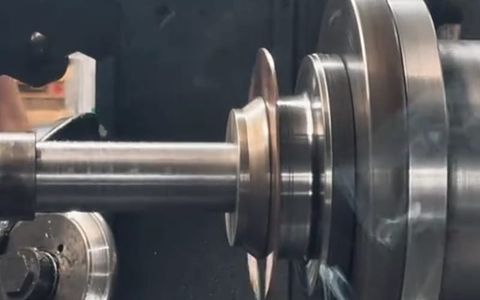

The modernization of metal spinning is driven primarily by the adoption of Computer Numerical Control (CNC) technology, which replaces traditional hand spinning with automated, programmable forming processes. CNC metal spinning follows precise CAD-based tool paths to control forming rollers and tooling, ensuring repeatable and highly accurate results across production runs.

Unlike manual spinning, CNC metal spinning minimizes operator dependency and enables continuous, high-volume manufacturing with tight tolerances and consistent quality.

Key Advantages of CNC Metal Spinning

- Higher accuracy and repeatability across entire production runs

- Reduced human error, thanks to automated tool paths and minimized manual intervention

- Lower labor requirements, enabling efficient 24/7 production

- Improved cost efficiency for medium- to high-volume manufacturing

- Scalability, from prototype development to mass production

Expanded Material Capabilities

CNC metal spinning allows manufacturers to form a broader range of materials compared to traditional hand spinning, including metals with lower ductility. Common materials include:

- Aluminum and aluminum alloys

- Stainless steel

- Cold-rolled carbon steel

- Copper

- Brass

This expanded material range enables CNC spinning to serve a wider variety of industrial sectors, including automotive, aerospace, energy, HVAC, lighting, and industrial equipment manufacturing.

A Smarter Manufacturing Choice

By combining automation, precision, and cost control, CNC metal spinning has become a strategic manufacturing solution for producing axisymmetric metal components with excellent structural integrity and surface quality. When incorporated early in the design stage, CNC spinning delivers measurable advantages in lead time, cost, and part performance.

As a professional metal spinning manufacturer, KMS provides comprehensive engineering support and advanced CNC spinning capabilities to produce metal components of all shapes and sizes. Contact our engineering team to explore how modern CNC metal spinning can optimize your next project.

English

English

Deutsch

Deutsch

Русский

Русский

العربيّة

العربيّة