Main Features of Metal Spinning Technology

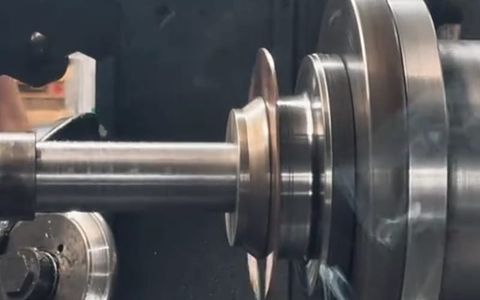

Mechanical metal spinning is an incremental, localized metal forming process performed under cold or hot conditions. It is widely used to manufacture axisymmetric hollow components with high structural integrity and excellent surface quality.

Overview

Metal spinning is a precision forming process in which a flat metal disc or tubular blank is securely mounted onto a mandrel and rotated at high speed by the spindle of a spinning lathe. One or more forming rollers apply controlled pressure to the rotating workpiece, progressively shaping it point by point and layer by layer until it conforms precisely to the mandrel geometry. The result is a seamless, axisymmetric hollow component with tight dimensional control.

Main Features

High material utilization: Near-net-shape forming with minimal material waste.

Superior mechanical properties: Grain refinement and continuous fiber flow significantly enhance strength, hardness, and fatigue resistance.

High production flexibility: Tooling costs are low; product changes typically require only mandrel replacement, making the process ideal for prototyping and small-to-medium batch production.

Excellent surface finish: Smooth inner and outer surfaces reduce or eliminate secondary machining.

Core Product Applications

Automotive Wheel Rims

Process: Strong (flow) spinning of aluminum alloy rims for trucks, buses, specialty vehicles, and premium passenger cars.

Value: Compared with cast wheels, spun rims offer reduced weight, increased strength, and improved fatigue performance—key enablers of vehicle lightweighting.

Pressure Vessels and Cylinders

Process: Spinning, necking, and closing operations used to form sealed ends of gas cylinders and storage tanks.

Value: Enables thin-wall, high-pressure containers widely used in fire protection, medical systems, aerospace, and energy industries.

Automotive Exhaust Components

Process: Forming tapered pipes, reducers, and variable cross-section exhaust components.

Value: Ensures smooth exhaust flow while meeting thermal resistance and packaging requirements, typically using heat-resistant stainless steel.

Suspension System Shock Absorber Housings

Process: Precision spinning of aluminum alloy outer cylinders with uniform wall thickness and smooth internal surfaces.

Value: Directly impacts vehicle handling and safety while achieving lightweight structural performance.

Materials Commonly Used

Aluminum alloys: Lightweight, excellent formability; ideal for rims and suspension housings.

Stainless steel: Corrosion-resistant and durable; used in pressure vessels, exhaust systems, and architectural components.

Carbon steel: High strength and cost-effective for industrial structural parts.

Copper & brass: Electrical and decorative applications.

Titanium & titanium alloys: Aerospace and medical applications (typically hot spinning).

Nickel-based superalloys: High-temperature aerospace engine components (hot spinning required).

Semi-Finished Forms

Discs: For closed-end or open-end parts such as rims and vessel heads.

Tube blanks: For cylindrical components like gas cylinders and shock absorber housings.

Pre-stamped blanks: Improve forming limits and production efficiency.

Ordinary vs. Strong Spinning

Conventional spinning: Minimal wall thickness change; primarily shape forming.

Strong spinning (flow forming): Controlled wall thinning with diameter expansion, enabling high-strength, thin-walled components such as rims and pressure vessels.

Industry Applications

Aerospace, energy & chemical processing, industrial equipment, lighting, and high-end consumer hardware.

English

English

Deutsch

Deutsch

Русский

Русский

العربيّة

العربيّة