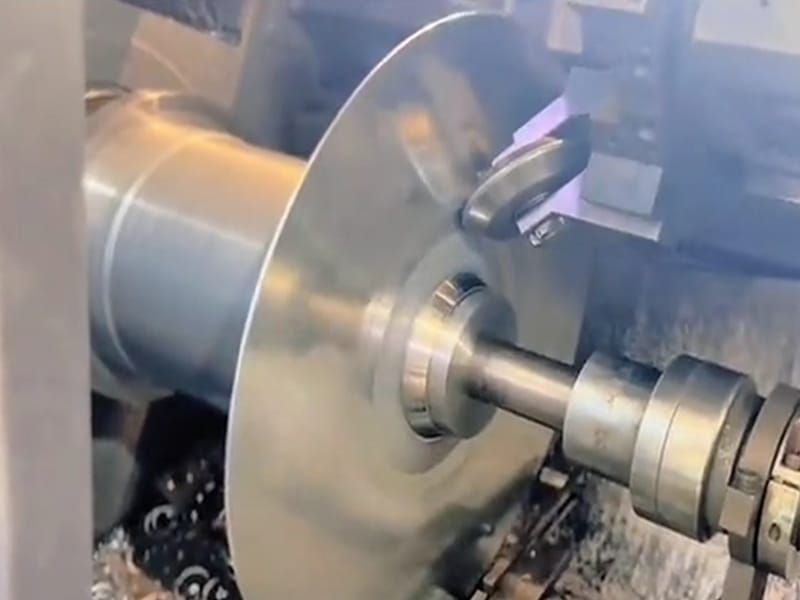

Precision CNC Metal Spinning of Stainless Steel Dome Covers for High-End Industrial Screening Equipment

The industrial screening equipment sector requires exceptional dimensional accuracy, sealing integrity, and premium surface finish for critical components. The customer is a leading Singapore-based screening equipment manufacturer and a global leader in material classification systems used in mining, chemical processing, and bulk material handling industries.

Precision CNC Metal Spinning of Stainless Steel Dome Covers for High-End Industrial Screening Equipment

1. Industry Background

The industrial screening equipment sector requires exceptional dimensional accuracy, sealing integrity, and premium surface finish for critical components. The customer is a leading Singapore-based screening equipment manufacturer and a global leader in material classification systems used in mining, chemical processing, and bulk material handling industries.

The key requirement was a custom stainless steel spun dome cover, serving as the upper sealing and protective enclosure of the screening machine. This component must provide:

- Ultra-high dimensional precision for perfect assembly fit

- Seamless, weld-free construction

- Mirror-quality surface finish

- Long-term reliability in harsh industrial environments

Previously, the customer used stamped and welded assemblies, which resulted in:

- Visible weld seams

- Curvature deviation up to ±0.5 mm

- Poor sealing performance causing material leakage

- Rough surface finish affecting product positioning in the premium market

To resolve these issues, the customer required a precision CNC metal spinning solution with seamless forming and superior dimensional control.

2. Customer Selected Solution

Custom CNC metal spun AISI 304 stainless steel dome cover

Technical Specifications

- Outer diameter: Ø680 mm

- Height: 180 mm

- Geometry: Smooth hemispherical dome profile

- Mounting holes: 12 evenly distributed flange holes

Wall Thickness

- Main wall thickness: 3.0 ± 0.1 mm

- Reinforced mounting flange thickness: 4.5 mm

Material Properties

- Material: AISI 304 Stainless Steel (EN 1.4301 / ASTM A240)

- Tensile strength: ≥ 520 MPa

- Yield strength: ≥ 205 MPa

- Excellent corrosion resistance and mechanical strength

Surface Finish

- Mirror polished finish

- Surface roughness: Ra ≤ 0.3 μm

- Completely free of weld marks, scratches, or defects

3. Core Manufacturing Process

3.1 Raw Material Selection and Pre-Processing

- ASTM A240 certified stainless steel sheets with thickness tolerance ±0.05 mm

- Ultrasonic inspection ensuring defect-free material structure

- CNC laser cutting with precision ±0.03 mm

- Edge chamfering (R1.2 mm) for stress control

- Stress-relief annealing at 300°C to eliminate residual stresses

This ensures dimensional stability during spinning.

3.2 Precision CNC Metal Spinning Process (Key Technology)

Manufactured using a high-precision dual-roller CNC metal spinning machine, featuring:

- Servo-controlled positioning accuracy: ±0.005 mm

- Real-time pressure feedback system

- Laser distance measurement for dynamic correction

- CAD/CAM programmed tool path optimization

Proprietary Three-Stage Progressive Metal Spinning Process:

Stage 1: 25% reduction – primary dome formation

Stage 2: 20% reduction – curvature refinement and wall thickness control

Stage 3: 10% reduction – final precision shaping

Process benefits:

- Seamless, weld-free construction

- Curvature deviation ≤ 0.1 mm

- Wall thickness variation ≤ 0.05 mm

Temperature controlled between 25–35°C to prevent dimensional distortion.

3.3 Precision Machining and Flange Processing

- Custom precision fixtures (±0.01 mm positioning accuracy)

- 5-axis CNC machining for mounting hole processing

- Hole tolerance: ±0.03 mm

- Hole position tolerance: ±0.05 mm

- Edge finishing with axial runout ≤ 0.04 mm

Ensures perfect sealing fit.

3.4 Mirror Surface Finishing Process

Three-stage polishing process:

Stage 1: Diamond abrasive grinding (800 grit)

Stage 2: Aluminum oxide polishing (1200 grit)

Stage 3: Fine mirror polishing (2000 grit)

Final surface roughness:

Ra ≤ 0.3 μm (mirror finish)

Followed by:

- Ultrasonic cleaning

- Passivation treatment

- Enhanced corrosion resistance

- Long-term surface stability

3.5 Quality Control and Testing

Inspection methods include:

- CMM dimensional inspection of 16 critical dimensions

- Tolerance control ≤ ±0.08 mm

- Air pressure sealing test at 0.4 MPa (zero leakage)

- 240-hour salt spray corrosion test

- 100% visual inspection before delivery

4. Our Core Advantages

Ultra-High Precision Metal Spinning

- Dimensional tolerance: ±0.08 mm

- Curvature accuracy ≤ 0.1 mm

- Exceeds industry standards

Seamless One-Piece Construction

Compared with welded assemblies:

- Eliminates weld defects

- Improves structural integrity

- Enhances sealing performance

Premium Mirror Surface Finish

Mirror polishing and passivation provide:

- Ra ≤ 0.3 μm surface finish

- Superior corrosion resistance

- Premium aesthetic quality

International Project Execution Capability

- Dedicated engineering communication team

- Sample validation and batch traceability

- Production yield rate: 99.9%

- Lead time reduced by 15% compared to industry average

5. Quality Validation Results

Dimensional Accuracy

Assembly gap:

≤ 0.1 mm

100% installation compatibility achieved.

Surface Quality Validation

Customer confirmed:

- Seamless mirror finish

- Superior appearance compared to competitors

No corrosion or defects after long-term use.

Performance Validation

After 12 months continuous operation:

- No deformation

- No leakage

- No structural failure

Fully suitable for harsh mining and industrial environments.

Compliance Certification

- ISO 9001 certified manufacturing process

- Meets international industrial equipment standards

- Approved for global supply chain integration

6. Customer Problems Successfully Solved

Precision and Fit Issues

Improved assembly compatibility:

from 85% → 100%

Eliminated material leakage.

Surface Quality Issues

Achieved seamless mirror finish.

Enhanced customer's premium product positioning.

Reliability Issues

Seamless metal spinning eliminated weld failure risks.

Extended maintenance intervals by 3×.

Global Supply and Delivery Requirements

Established long-term partnership with repeat production orders.

English

English

Deutsch

Deutsch

Русский

Русский

العربيّة

العربيّة