Shear Spinning

Shear spinning and flow forming are advanced metal spinning techniques that allow precise control over wall thickness, shape, and surface quality for a wide range of industrial applications.

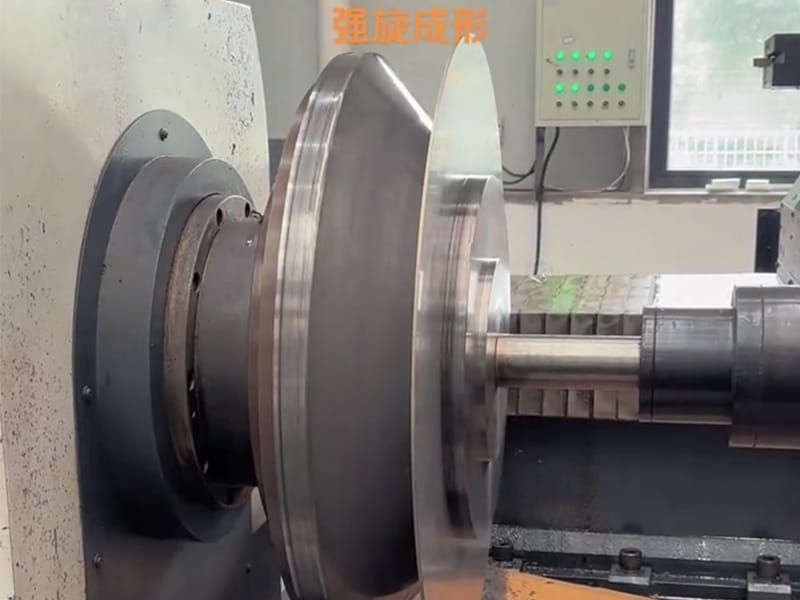

Shear Spinning

Shear spinning, also called shear forming, shapes sheet metal over a rotating conical mandrel, typically on a conventional spinning machine. Wall thickness is reduced while the original blank diameter is maintained. The roller forms the blank while applying compressive force, stretching the material in a single pass. Shear angles typically range from 12° to 18° (maximum 80°), and cylindrical shapes cannot be formed due to vertical walls.

Flow Forming

Flow forming (tube spinning) reduces wall thickness while increasing the length of a tubular blank. Dedicated flow forming equipment with multiple rollers applies localized radial pressure to create rotationally symmetrical hollow parts. Tubular blanks should have low flow stress, high tensile-to-yield strength ratio, high elongation, and high reduction in area.

Applications

Shear spinning and flow forming enable economical production of a variety of products, including vases, bowls, cones, kettles, blower housings, fans, filters, nozzles, ladles, funnels, venturis, domes, and drums. These processes offer high precision, excellent surface finish, and scalable production from prototypes to mass production.

contact us and Request A Quote

English

English

Deutsch

Deutsch

Русский

Русский

العربيّة

العربيّة