CNC Metal Spinning of Aluminum Motor Housing for New Energy Vehicle (NEV)

The New Energy Vehicle (NEV) industry is rapidly advancing toward lightweight construction, higher efficiency, and enhanced reliability. Our client, a leading EV manufacturer, developed a next-generation electric vehicle platform emphasizing extended driving range and high-performance powertrain systems.

1. Industry Background

The New Energy Vehicle (NEV) industry is rapidly advancing toward lightweight construction, higher efficiency, and enhanced reliability. Our client, a leading EV manufacturer, developed a next-generation electric vehicle platform emphasizing extended driving range and high-performance powertrain systems.

The electric motor housing is a critical structural component, required to operate under demanding conditions of:

- High rotational speed: up to 15,000 RPM

- Continuous high mechanical load

- Strict requirements for:

- Structural integrity

- Thermal dissipation efficiency

- Lightweight performance

- Dimensional precision

Previously, the client used conventional casting processes, which resulted in:

- Uneven wall thickness: ±0.5 mm deviation

- Excessive weight: 3.2 kg per unit

- Suboptimal heat dissipation

- Reduced motor efficiency and service life

The client required a precision metal spinning solution to overcome these limitations.

2. Product Specifications

Custom CNC Spun Aluminum Motor Housing

- Outside diameter: Ø280 mm

- Height: 150 mm

- Geometry: Cylindrical housing with integrated top flange for motor end cap mounting

Wall Thickness:

- Main body: 2.0 ± 0.1 mm

- Reinforced flange section: 4.0 mm

Material:

- Aluminum Alloy: 6061

- Tensile strength: ≥ 240 MPa

- Yield strength: ≥ 210 MPa

- Excellent formability and structural strength

- Compliant with GB/T 3880.1-2012 standard

Surface Treatment:

- Hard anodizing (Black)

- Oxide thickness: 12–15 μm

- Improved corrosion resistance and thermal conductivity

3. Core Manufacturing Process

3.1 Raw Material Preparation

- High-purity 6061 aluminum sheet (≥ 99.8% purity)

- Verified using spectrographic analysis

- CNC laser cutting with ±0.05 mm tolerance

- Edge chamfering (R1.5 mm) to eliminate stress concentration

3.2 Thermal Conditioning

Preheating at 220°C for 30 minutes to:

- Improve material ductility

- Reduce springback

- Ensure dimensional stability during spinning

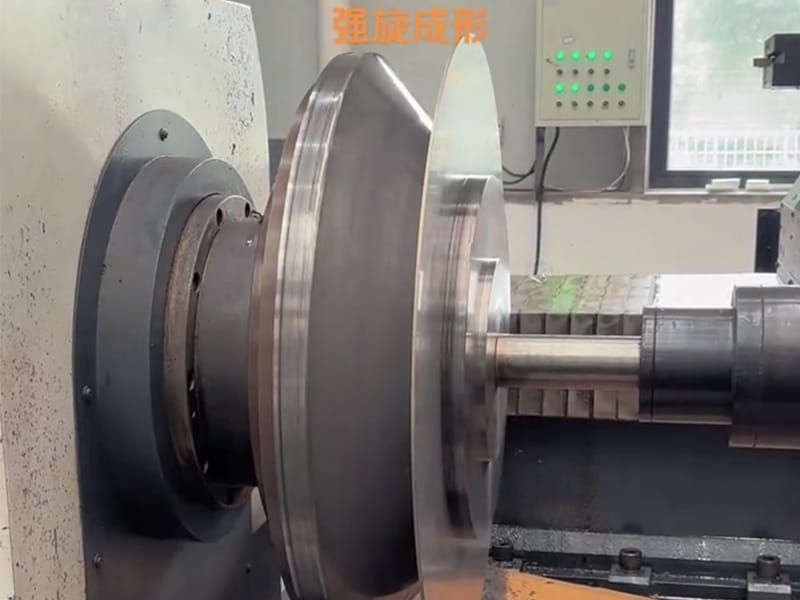

3.3 CNC Metal Spinning Process

Manufactured using a 3-roller CNC metal spinning machine (Japan-imported).

Multi-pass progressive spinning sequence:

- Pass 1: 30% reduction — primary forming

- Pass 2: 20% reduction — dimensional refinement

- Pass 3: 10% reduction — final precision forming

Real-time wall thickness monitoring ensured:

- Wall thickness uniformity: ≤ ±0.1 mm

- Seamless, weld-free structure

3.4 Secondary CNC Machining

Post-spinning precision machining includes:

- CNC turning of mounting flange

- Facing and dimensional finishing

Precision achieved:

- Face runout: ≤ 0.05 mm

- Mounting hole tolerance: ±0.03 mm

Ensures precise motor assembly alignment.

3.5 Surface Treatment: Hard Anodizing

Industrial sulfuric acid anodizing process:

- Degreasing and acid cleaning

- Electrochemical oxidation at 18–22°C and 15–18V

- Uniform, dense anodic oxide layer

- Sealing treatment for enhanced corrosion resistance

3.6 Quality Control and Inspection

Full-process quality assurance includes:

- Material verification (spectrometer analysis)

- Dimensional inspection

- In-process thickness monitoring

- CMM full dimensional scanning

- Coating thickness measurement

- Salt spray corrosion testing

- Air-tightness testing: 0.3 MPa pressure, 30-minute hold, zero leakage

4. Our Technical Advantages

4.1 Advanced Metal Spinning Technology

Compared to casting, CNC metal spinning provides:

- Seamless, weld-free structure

- Improved mechanical strength (+30%)

- Enhanced structural integrity

- Superior surface finish

Equipped with:

- Multi-axis CNC spinning machines

- Experienced programming engineers

- Full OEM/ODM customization capability

4.2 High Precision Control

Achieved dimensional tolerance:

±0.05 mm

Significantly exceeding client requirement of ±0.2 mm

Inspection equipment includes:

- Coordinate Measuring Machine (CMM)

- Ultrasonic thickness gauge

- Precision runout measurement systems

4.3 Lightweight Optimization

Weight reduced from:

3.2 kg → 2.2 kg

Weight reduction: 30%

Benefits:

- Improved vehicle driving range: +8–10%

- Reduced energy consumption

- Enhanced power efficiency

4.4 Integrated Thermal Management Design

Integrated 36 cooling grooves formed during spinning:

- Groove dimensions: 2 mm width × 1 mm depth

- No secondary machining required

- Improved heat dissipation efficiency by 25%

4.5 High Production Efficiency

Production capacity:

- 200 units per day per machine

- Monthly production capacity: 5,000+ units

- Lead time reduced by 20% compared to industry average

Supports full-scale mass production.

5. Product Validation and Performance Results

Thermal Performance

Motor housing temperature reduced by:

12°C lower than cast housing after 8-hour continuous operation

Structural Durability

Passed vibration testing:

- Frequency: 5–500 Hz

- Acceleration: 20 g

- 100,000 cycles

Results:

- No deformation

- No cracking

- Excellent structural stability

Material and Surface Performance

Measured tensile strength:

256 MPa

Salt spray resistance:

480 hours with no corrosion

100% dimensional inspection pass rate via CMM

Certification and Compliance

Certified under:

- IATF 16949 Automotive Quality Management System

- GB/T 28046.3-2011 Automotive Environmental Standards

Approved as qualified supplier in client's core supply chain.

6. Customer Value and Problem Resolution

Lightweight Solution

30% weight reduction improved vehicle driving range by 8–10%

Precision and Assembly Improvement

Improved dimensional accuracy reduced:

- Assembly tolerance issues

- Mechanical noise

Results:

- Assembly efficiency improved by 40%

- Noise reduced by 3 dB

Thermal Performance Improvement

Heat dissipation improved by:

25%

Motor service life extended to:

10 years or 300,000 km

Mass Production Capability

Stable supply capacity:

5,000+ units per month

Ensured reliable production schedule for vehicle launch.

English

English

Deutsch

Deutsch

Русский

Русский

العربيّة

العربيّة