Power and Force Requirements

Power and Force Requirements

Spinning large metal cylinders requires substantial power and forming force, far exceeding the capabilities of conventional metal spinning machines.

Power and Force Requirements in Large-Diameter Metal Spinning

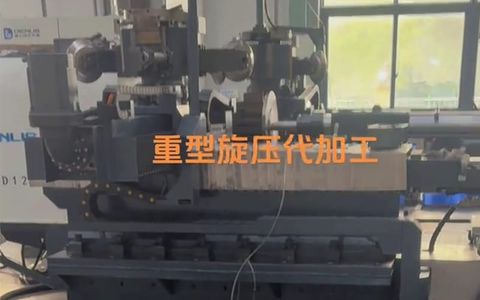

The metal spinning of large and thick-walled cylinders demands exceptionally high power output and forming forces. During the process, heavy-gauge metal blanks are plastically deformed into precise cylindrical geometries, requiring significant axial thrust and radial forming forces to achieve controlled material flow without compromising structural integrity.

For example, forming thick steel blanks requires machines capable of delivering extremely high pressure to ensure uniform deformation while preventing defects such as cracking, wrinkling, or excessive thinning. Maintaining dimensional accuracy and mechanical performance under such conditions is only possible with high-capacity, heavy-duty spinning equipment.

Conventional spinning machines are often inadequate for these applications. Their limited force capacity, lower spindle torque, and insufficient structural rigidity can result in process instability, inconsistent wall thickness, and potential damage to both the machine and the workpiece.

As a result, large-scale metal cylinder fabrication necessitates the use of high-tonnage CNC spinning machines, reinforced machine frames, and advanced drive systems designed to withstand extreme forming loads. These robust systems enable stable, repeatable, and safe production of large-diameter cylindrical components.

Contact us and Request A Quote

English

English

Deutsch

Deutsch

Русский

Русский

العربيّة

العربيّة