Maintaining Structural Integrity

Maintaining Structural Integrity

Maintaining structural integrity during the spinning of large metal cylinders is essential to ensure the final product meets stringent industrial standards.

Maintaining Structural Integrity

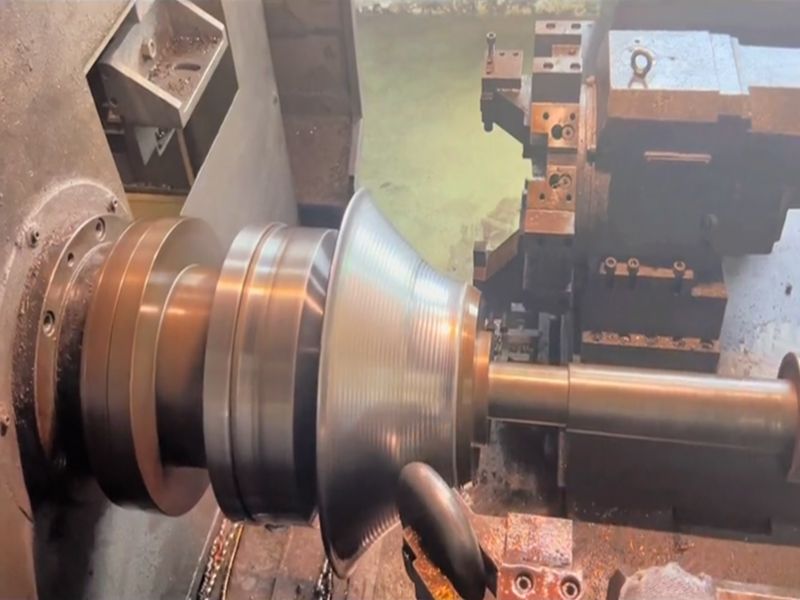

Maintaining structural integrity throughout the spinning of large metal cylinders is critical to achieving reliable, high-performance components. One of the primary challenges lies in preventing defects such as wrinkling, tearing, cracking, or uneven wall thickness—issues that can arise due to the extreme stresses imposed during forming. These imperfections may significantly compromise the cylinder’s mechanical performance, dimensional accuracy, and long-term reliability, particularly in applications requiring high structural strength and precision.

Consistent material quality and uniform mechanical properties are key factors in mitigating these risks. Variations in tensile strength, ductility, or grain structure can cause unpredictable material behavior during spinning, increasing the likelihood of defects. Selecting high-quality materials with controlled and consistent properties ensures the metal can withstand high forming forces without failure.

Equally important is precise control of process parameters, including forming temperature, spindle speed, feed rate, and forming force. Optimizing these variables allows for stable material flow and helps preserve the structural integrity of the workpiece throughout the entire spinning process.

Contact us and Request A Quote

English

English

Deutsch

Deutsch

Русский

Русский

العربيّة

العربيّة